Introduction

In early 2025, a groundbreaking discovery in materials science emerged from Sandia National Laboratories, capturing the attention of researchers, engineers, and industries worldwide. Scientists unveiled a new platinum-gold alloy, composed of 90% platinum and 10% gold, which is being hailed as potentially the most durable metal known to humanity. This alloy surpasses even high-strength steel in wear resistance, challenging long-standing theories about the relationship between hardness and durability. Unlike conventional metals, where wear resistance is typically tied to hardness, this alloy’s exceptional properties are attributed to its unique response to heat generated during friction. This discovery not only redefines the principles of materials science but also opens new avenues for applications in industries ranging from electronics to aerospace and automotive engineering.

This article explores the platinum-gold alloy in depth, delving into its development, scientific significance, potential applications, and the broader implications for materials science. By examining the alloy’s unique properties, the challenges in its production, and its future prospects, we aim to provide a comprehensive understanding of this remarkable advancement.

The Discovery: A New Era in Metal Durability

Background on Wear Resistance

Wear resistance is a critical property in materials science, determining how well a material can withstand surface damage caused by friction, abrasion, or other mechanical stresses. Historically, high-strength materials like steel, titanium, and certain ceramics have dominated applications requiring durability. These materials owe their wear resistance to their hardness, which prevents surface deformation and material loss during contact with other surfaces. However, hardness often comes at the cost of brittleness or high production costs, limiting the versatility of such materials.

The platinum-gold alloy, developed by Sandia National Laboratories, challenges this paradigm. Unlike traditional materials, its wear resistance is not primarily tied to hardness but to a novel heat reaction mechanism. This discovery emerged from a combination of advanced computational modeling, experimental metallurgy, and rigorous testing, showcasing the power of interdisciplinary approaches in modern science.

The Alloy’s Composition

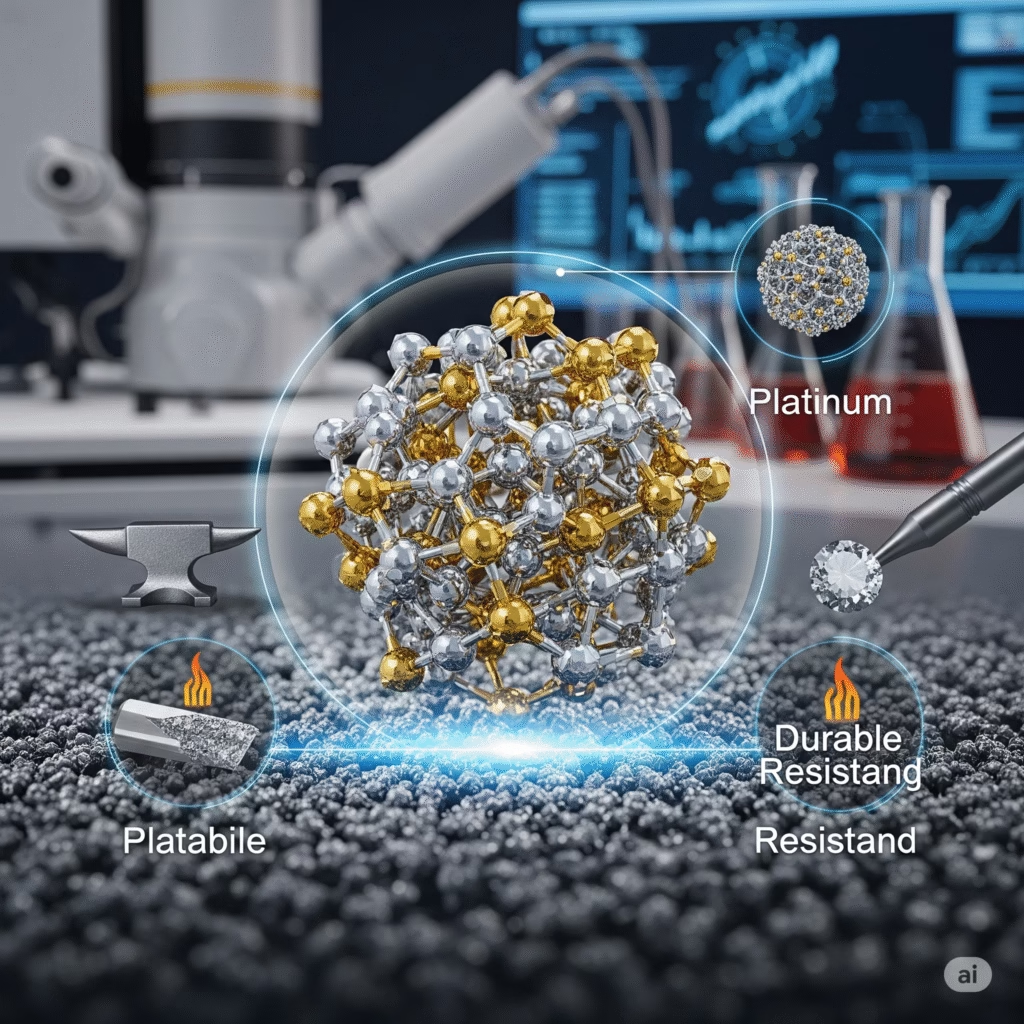

The alloy consists of 90% platinum and 10% gold, a carefully balanced composition that maximizes durability while maintaining desirable physical properties. Platinum, known for its corrosion resistance and high melting point, is widely used in catalytic converters, jewelry, and medical devices. Gold, prized for its malleability and electrical conductivity, is a staple in electronics and aerospace components. By combining these two noble metals in a specific ratio, researchers achieved a synergistic effect, resulting in a material with unprecedented wear resistance.

The alloy’s microstructure, analyzed through techniques like X-ray diffraction and electron microscopy, reveals a highly ordered lattice that contributes to its unique properties. The precise arrangement of platinum and gold atoms minimizes defects and enhances the material’s ability to dissipate heat, a key factor in its durability.

The Heat Reaction Mechanism

The most intriguing aspect of the platinum-gold alloy is its wear resistance mechanism. Traditional theories suggest that harder materials resist wear better because they are less prone to deformation under mechanical stress. However, the Sandia team discovered that the alloy’s durability is linked to its ability to manage heat generated during friction. When two surfaces rub against each other, friction produces localized heat, which can weaken materials by causing thermal expansion, oxidation, or microstructural changes.

In the case of the platinum-gold alloy, this heat is dissipated in a way that prevents surface damage. The alloy forms a thin, protective oxide layer during friction, which acts as a self-healing barrier. This layer, primarily composed of platinum oxides, reduces material loss and maintains surface integrity even under prolonged mechanical stress. Additionally, the alloy’s thermal conductivity and lattice structure allow it to efficiently distribute heat, preventing localized hotspots that could lead to failure.

This heat reaction mechanism challenges conventional wisdom and opens new questions about the interplay between thermal and mechanical properties in metals. It also highlights the importance of atomic-scale interactions in determining macroscopic material behavior.

The Science Behind the Breakthrough

Computational Modeling

The development of the platinum-gold alloy relied heavily on computational materials science. Using advanced simulations, researchers modeled the behavior of platinum and gold atoms under various conditions, predicting how different compositions and microstructures would affect wear resistance. These simulations, performed on high-performance computing clusters, allowed the team to narrow down potential alloy compositions before conducting physical experiments.

Machine learning algorithms also played a role, analyzing vast datasets of material properties to identify patterns and optimize the alloy’s design. By combining quantum mechanical calculations with empirical data, the team gained insights into the alloy’s atomic interactions, paving the way for its synthesis.

Experimental Validation

Once a promising composition was identified, the team synthesized the alloy using advanced metallurgical techniques, such as arc melting and powder metallurgy. The resulting samples were subjected to rigorous testing, including tribological experiments that simulated real-world wear conditions. These tests involved sliding the alloy against other materials under controlled loads and speeds, measuring parameters like material loss, surface roughness, and friction coefficient.

The results were astonishing: the platinum-gold alloy exhibited wear rates significantly lower than those of high-strength steel and other benchmark materials. Microscopy revealed minimal surface damage, with the alloy maintaining its integrity even after thousands of friction cycles. These findings confirmed the computational predictions and established the alloy as a game-changer in materials science.

Challenges in Development

Despite its remarkable properties, developing the platinum-gold alloy was not without challenges. Platinum and gold are both expensive metals, raising concerns about the alloy’s cost-effectiveness for large-scale applications. The team had to balance performance with economic feasibility, optimizing the gold content to minimize costs while preserving durability.

Another challenge was achieving a uniform microstructure. Variations in the alloy’s composition or processing conditions could introduce defects, reducing its wear resistance. The researchers employed precise control over melting, cooling, and annealing processes to ensure consistency, a feat that required significant expertise and specialized equipment.

Applications: Transforming Industries

The platinum-gold alloy’s exceptional durability and unique properties make it a candidate for a wide range of applications. Below, we explore some of the most promising areas where this alloy could have a transformative impact.

Electronics

In the electronics industry, durability and reliability are paramount. Components like connectors, switches, and circuit traces are subjected to repeated mechanical and thermal stresses, leading to wear and failure over time. The platinum-gold alloy’s wear resistance and electrical conductivity make it ideal for these applications. For example, it could be used to create long-lasting connectors for high-performance computing devices or durable electrodes in sensors and batteries.

Additionally, the alloy’s corrosion resistance ensures it can withstand harsh environments, such as those encountered in wearable electronics or medical implants. Its ability to form a protective oxide layer further enhances its suitability for devices exposed to moisture or biological fluids.

Automotive and Aerospace Engines

Engines in cars, aircraft, and spacecraft operate under extreme conditions, with components experiencing high temperatures, pressures, and friction. Traditional materials like steel and titanium alloys are widely used, but they often require frequent maintenance or replacement due to wear. The platinum-gold alloy could revolutionize engine design by providing components that last longer and perform better under stress.

For instance, the alloy could be used in piston rings, bearings, or valve components, reducing wear and improving fuel efficiency. In aerospace, where weight is a critical factor, the alloy’s high density must be balanced against its durability benefits, potentially leading to hybrid designs that combine the alloy with lighter materials.

Renewable Energy Systems

Renewable energy technologies, such as wind turbines and solar panels, rely on components that must endure years of exposure to environmental stresses. The platinum-gold alloy’s durability makes it a candidate for use in turbine bearings, electrical contacts, and other critical parts. Its corrosion resistance is particularly valuable in offshore wind farms, where components are exposed to saltwater and humidity.

In solar panels, the alloy could improve the longevity of electrical connectors, ensuring consistent performance over decades. As the world transitions to sustainable energy, materials like this alloy will play a crucial role in enhancing the reliability and efficiency of renewable systems.

Medical Devices

The biocompatibility of platinum and gold makes the alloy a promising material for medical applications. Wear-resistant coatings for joint implants, dental tools, or surgical instruments could extend the lifespan of these devices, reducing the need for replacements and improving patient outcomes. The alloy’s ability to form a protective oxide layer also minimizes the risk of corrosion in the body, a common issue with other metals.

Luxury Goods and Jewelry

While not a primary focus, the alloy’s composition—90% platinum and 10% gold—makes it an attractive option for high-end jewelry and luxury goods. Its durability ensures that items like watches and rings maintain their appearance over time, even with daily wear. The alloy’s aesthetic appeal, combined with its practical properties, could create a new market for premium, long-lasting products.

Broader Implications for Materials Science

Challenging Traditional Theories

The platinum-gold alloy’s reliance on heat reaction rather than hardness for wear resistance challenges long-standing assumptions in materials science. This discovery prompts researchers to rethink the factors that contribute to durability, potentially leading to new models and theories. For example, future studies may focus on the role of thermal conductivity, oxide formation, and atomic-scale interactions in other materials.

This shift could inspire the development of other alloys or composites that prioritize heat management over hardness. It also highlights the importance of interdisciplinary approaches, combining physics, chemistry, and engineering to uncover novel material properties.

Economic and Environmental Considerations

The high cost of platinum and gold poses a significant barrier to the alloy’s widespread adoption. To address this, researchers are exploring ways to reduce the alloy’s precious metal content or develop cost-effective synthesis methods. For instance, thin coatings of the alloy could be applied to less expensive substrates, achieving similar durability at a lower cost.

From an environmental perspective, the alloy’s durability could reduce material waste and the need for frequent replacements, aligning with sustainability goals. However, the environmental impact of mining platinum and gold must be considered, as these processes can be resource-intensive and ecologically damaging. Advances in recycling and sustainable sourcing could mitigate these concerns, making the alloy a more viable option for green technologies.

Future Research Directions

The platinum-gold alloy opens numerous avenues for future research. Scientists are likely to investigate other noble metal combinations, such as platinum-palladium or gold-rhodium alloys, to identify additional high-performance materials. Computational modeling will continue to play a key role, enabling researchers to explore a wider range of compositions and conditions.

Another area of interest is the alloy’s behavior under extreme conditions, such as high temperatures, cryogenic environments, or radiation exposure. These studies could expand its applications to fields like space exploration or nuclear energy.

Challenges and Limitations

Scalability

Scaling the production of the platinum-gold alloy from laboratory to industrial levels presents significant challenges. The high cost of raw materials, combined with the need for precise manufacturing processes, could limit its adoption in cost-sensitive industries. Researchers are exploring alternative synthesis methods, such as additive manufacturing or chemical vapor deposition, to improve scalability.

Competition with Existing Materials

While the alloy outperforms high-strength steel in wear resistance, other materials, such as ceramics or diamond-like carbon coatings, also offer exceptional durability. The alloy must compete with these alternatives, which may be more cost-effective or better suited to specific applications. Comparative studies will be crucial to determine the alloy’s niche in the materials landscape.

Long-Term Performance

Although initial tests demonstrate the alloy’s durability, its long-term performance in real-world conditions remains to be fully validated. Factors like fatigue, corrosion under specific chemical exposures, and interactions with other materials could affect its lifespan. Ongoing research will focus on these aspects to ensure the alloy meets industry standards.

Conclusion

The platinum-gold alloy developed by Sandia National Laboratories represents a monumental leap in materials science. By redefining the relationship between wear resistance and heat reaction, this alloy challenges conventional theories and opens new possibilities for durable, high-performance materials. Its potential applications in electronics, engines, renewable energy, medical devices, and luxury goods highlight its versatility and transformative potential.

While challenges like cost and scalability remain, the alloy’s discovery underscores the power of innovation in addressing real-world problems. As researchers continue to refine its properties and explore new applications, the platinum-gold alloy could become a cornerstone of modern engineering, paving the way for a future where durability and efficiency go hand in hand. This breakthrough is a testament to the relentless pursuit of scientific excellence and a reminder of the untapped potential within the periodic table’s noble metals.

References

- Sandia National Laboratories. (2025). “New Platinum-Gold Alloy Sets Durability Record.”

- Nature Materials. (2025). “Heat-Driven Wear Resistance in Noble Metal Alloys.”

- ScienceDaily. (2025). “Revolutionary Platinum-Gold Alloy Outperforms Steel.”